AiRSensors, Inc. Publications

The Technology of Tuneable Horsepower (pdf)

The Technology of Tuneable Horsepower (pdf) Air Sensors Electronic Fuel Injection (pdf)

Air Sensors Electronic Fuel Injection (pdf) More HP and MPG for your Towing Rig or RV (pdf)

More HP and MPG for your Towing Rig or RV (pdf) Direct Port Fuel Injection (pdf)

Direct Port Fuel Injection (pdf) Creating a "Happy Camper" (pdf)

Creating a "Happy Camper" (pdf) Bolt-On Fuel Injection (pdf)

Bolt-On Fuel Injection (pdf)

The above documents were not created by Auto-nomics, but are provided as a service to our customers.

AiRSensors, Inc. History

A history of the company

The Company AiRSensors (ASI) designs, develops, manufactures and markets electronic fuel injection (EFI) systems for automobile, truck and boat engines. The company is the only supplier of EFI products to the United States aftermarket, and is aggressively pusuing the original equipment manufacturing market in Asia.

AiRSensors' products are based on advanced hot-wire anemometry which measures air mass. The company's patented air mass sensor and proprietary computer combine to deliver a very precisely controlled air-to-fuel mixture to an engines combustion chambers.

Incorporated in 1978, AiRSensors had its initial public offering of common stock in August, 1986. The stock trades in the Over-the-Counter market under the symbol ARSN.

The company was founded by Roland Brusco, a current director and major shareholder, as Advanced Fuel Systems, Inc. (AFS). AFS aquired patent rights to and undertook to develop a vaporized fuel system for internal combustion engines, a project which proved to be impractical.

With the arrival of the current chief executive (Mr. Douglas Toms) in October of 1980, the company's direction changed, and ASI engineers began design and development work on an air mass sensor. The design uses a well-known principle, and follows established automotive engineering concepts.

After the air mass sensor was developed, ASI moved on to design a complete electronic fuel injection system. One-, two- and four injector throttle-body models have been developed and manufactured. The one-injector model and port injection systems are aimed at the automotive original equipment market. An ASI four-injector system, matched with a supercharger, is sold in the U.S. aftermarket by B&M Automotive Products.

AiRSensors' basic business is developing technology and products using hot-wire anemometry. The company's principal focus has been on the development and manufacture of high quality, reliable air mass sensors.

The heart of the sensor is a platinum wire which is electrically heated. The wire is located in a conduit through which air passes. The current required to maintain the wire's fixed temperature is a function of air mass, which is computed with solid state electronic circuitry. This circuitry, and the method of assembly are proprietary and are patented.

The air mass signal generated by the device can be used in a variety of applications. In automotive use, the precise mass of air entering the combustion chamber is measured by the sensor, the corresponding amount of fuel for optimum combustion can be computed electronically. This, in turn can be adjusted for actual operating conditions, computed and metered into the combustion chamber.

Other potential uses for ASI air mass sensors (several of which are under investigation) include combustion control for boilers, furnaces and air speed or volume indicators.

AiRSensors' first automotive product is a single-point electronic fuel injection system designed to replace the conventional carburetor. Depending on the size of the engine, one, two of four electronically controlled fuel injectors are installed in an ASI throttlebody, which in turn is mounted to the engine's standard intake manifold.

The intake air mass signal and other engine data signals representing temperature, RPM, and ignition timing are processed by an ASI computer. It computes the optimum air-fuel ratio for operating conditions ranging from cold start to wide open throttle, and sends a time-regulated fuel signal to operate the injector(s). Improved combustion is achieved over a wide range of driving conditions, providing better performance, improved fuel economy and lower emission levels.

AiRSensors is developing a number of other products that are expected to reach the market in the near future: tuned-port multi-point electronic fuel injection systems; EFI systems for engines powered by compressed natural gas and/or liquified petroleum gas; a meter for measuring the flow of natural gas, and air-speed indicators for light aircraft and sailboats.

The above document was copied from early AiRSensors documents.

The Great Carburetor Alternative...

The Latest Story on High-Performance Fuel Injection

The following is a reprint of an early promotional document, and some details may be inaccurate.

Reprinted courtesy of Autotech Magazine

July 1988

AiRSensors

High-Performance Fuel Injection Aftermarket Bolt-On Has Carburetors Beat

by Greg Raven

"In the beginning man created the carburetor and rejetting kit. And man saw every thing that he had made, and, behold, it was very good."

If this sounds to you to be an accurate cosmology of automotive design, it's understandable. For years and years, carburetors were the only way of getting air and fuel in the proper mixture into the motor. If you wanted higher performance, you bolted on a bigger carburetor. When the first street fuel-injection systems began to appear, they were so alien to most hot rodders that their immediate reaction was to rip out the injectors, computers, wires, and sensors and slap on a good ol' carburetor.

Fuel injection has made great strides since the late '60s, and it is fast coming to the point where most cars will come with fuel injection as standard equipment. These OE injection set-ups are scarcely what the average do-it-yourselfer would consider tinkering with, however, as the sophistication required to change virtually anything about them is substantial.

Still, it was only a matter of time before someone came up with an aftermarket, bolt-on fuel injection aimed at the do-it-yourselfer, and that time is now.

|

|

AiRSensors components

|

One of the companies offering aftermarket electronic fuel injection (EFI) is AiRSensors, of Seattle, Washington. The current line-up of AiRSensors high-performance products includes four different fuel-injection systems, camshafts, replacement computer chips, exhaust systems, and turbochargers; but the heart of it all is an air-mass sensor similar to those found in the more sophisticated Bosch EFI systems.

|

|

Digital ECU

|

Air-mass sensors are the latest rage in EFI because of the precision with which they meter air. Previously, fuel-injection systems that relied on air metering, such as the Bosch K-Jetronic (continuous injection system) and L-Jetronic (EFI) used mechanical speed-density sensors. Air pushing against the sensor plate tells the fuel-injection system how much air is entering the motor. This not only adds a mechanical impedance to the airflow, it also fails to discriminate between dense air and thin air, both of which will displace the plate by the same amount as long as the velocity is the same.

|

|

AiRSensors Tuned Port Injection

|

In contrast, an air-mass sensor using the "hot wire" technology can be much more accurate. The "hot wire" is an electrically-heated platinum filament that sits in the engine intake airstream along with an ambient air temperature probe. The filament and the probe are part of a bridge circuit through which the current flow is balanced. As incoming air rushes past the sensor, some of the heat in the filament is lost to the air. Cooling the filament changes its conductivity, which in turn unbalances the circuit, increasing the current flow through the wire. The circuitry measures the amount of current used to bring the filament back up to temperature.

|

|

AiRSensors Multi-Point Fuel Injection

|

The computer looks at the ambient air temperature and the amount of additional current flow through the filament, and calculates the mass of the air that has entered the engine. Because the amount of cooling is directly proportional to the mass of the air flowing past the sensor, it becomes relatively simple to calculate how much fuel to inject for best performance and economy. Of course, the actual amount of fuel injected is adjusted according to the operating conditions of the engine based on inputs from engine rpm, ignition timing, and engine temperature sensors.

|

|

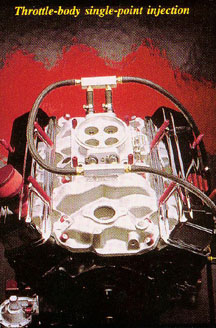

AiRSensors Throttle-Body Single-Point Injection

|

Once you get past the elementary physics of hot-wire anemometry (air measurement), the whole thing seems quite simple. In fact, it has just begun to get complicated. The hot wire only knows that air is rushing past it. It doesn't know which direction the air is headed. Each time an intake valve slams shut it sends a pulse back through the intake tract. Intake air that has just entered the sensor (and which has just been metered) is metered again as the pulse carries the air out past the hot wire. When the pulse subsides, the air is once again carried into the engine, for a total of three meterings of the same air.

The trick is to have an air-mass sensor reacting quickly enough to these pulses that the computer has a chance to deliver the correct signal to the injectors. Some hot-wire systems use a platinum-coated film with a response time of 50 to 60 milliseconds. Considering that the maximum injector pulse is only 10 milliseconds, the computer never gets the data it needs in order to make the necessary corrections.

|

|

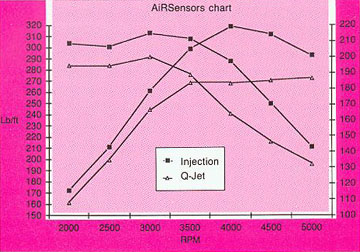

AiRSensors Chart

|

To get around this situation, the AiRSensors system uses platinum wire with a response time of 1.5 milliseconds. Every few nanoseconds, the AiRSensors computer samples the state of the air-mass sensor and the temperature probe and averages the data. This results in an averaged fuel delivery that is very close to the optimum amount of fuel needed by the engine.

Using the same air-mass sensor design as a starting point, AiRSensors has developed four systems: a throttle-body single -point fuel-injection carburetor replacement system capable of 375 horsepower, a tuned port-injection system capable of 450 horsepower, a multi-point injection system capable of 750 horsepower (1,200 horsepower when run in tandem), and a throttle-body single-point fuel-injection system for towing rigs and recreational vehicles. The first three of these systems feature digital controllers, while the last uses an analog controller.

Each of these controllers allow you to easily adjust performance parameters in a way we could only dream about when jets and jet reamers were all we had to work with. The analog controller gives access to the overall air/fuel ratio, the cold start mixture, the idle mixture, mixture under load, and mixture under acceleration.

The digital controller does all this and more, including putting the adjustments at your fingertips in a dash-mountable unit. Punch up the function you wish to adjust, turn the knob while looking at the LED readout, and immediately see the results.

Between the design of the air-mass sensor and the flexibility of the controllers, the AiRSensors fuel injections can be used with virtually any engine. Superchargers, turbochargers, and wild cams are all easy to adjust for. A four-gas analyzer, dynamometer, and/or exhaust gas-temperature readings are recommended when dialing in the injection, but the same holds true for accurate carburetor jetting.

Another amazing aspect of the AiRSensors fuel injection is in the traditionally carburetor-dominated area of throttle response. Street-driven fuel injection isn't supposed to be this good. On a built-up motor, the response is so immediate it can make you think the speedometer is connected directly to the accelerator pedal. The technology is new enough and the prices high enough that not everyone will be able to go for an AiRSensors system instead of a replacement carburetor. But judging by the acceptance these systems have found in the high-performance aftermarket, AiRSensors is giving the people exactly what they want.

AiRSensors and F.I.R.S.T. are trademarks of AiRSensors, Inc.

Auto-nomics is not affiliated with AiRSensors, Inc. or its successors.

The information in this web site is freely provided for personal use only, and is not intended for commercial purposes. Auto-nomics assumes no liability for consequences resulting from the use of any information provided here, and makes no claims as to the accuracy or suitability for use. Auto-nomics has sole rights to all print and image content unless otherwise noted.

Last updated on 10/1/11, 12:05 AM